Description

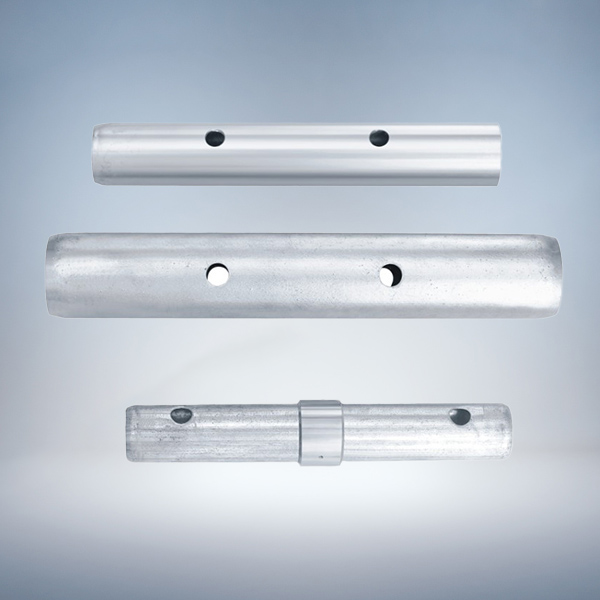

The bridge is located above the river and needed to be newly constructed without affecting the normal flow of the river. The construction team chose a Ringlock scaffolding because its high-strength steel components can withstand dynamic loads (such as vehicle vibration) and easily adapt to the curved design of the bridge. The scaffolding was erected in just half a month, 40% faster than traditional methods. Through segmented construction and nighttime operations, the project minimized river pollution. Ultimately, the bridge’s load-bearing capacity was increased by 50%, there were no safety accidents during construction, and it was delivered one month ahead of schedule, avoiding the impact of the river flood season. The adjustability, safety, and durability (corrosion-resistant treatment) of the Ringlock scaffolding are its core advantages.