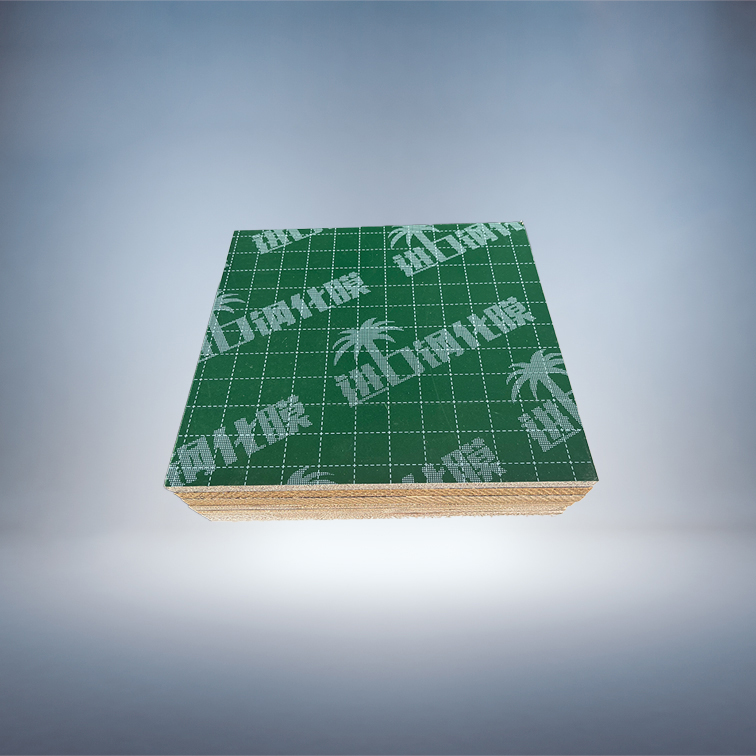

PP (Polypropylene) Membrane Plywood

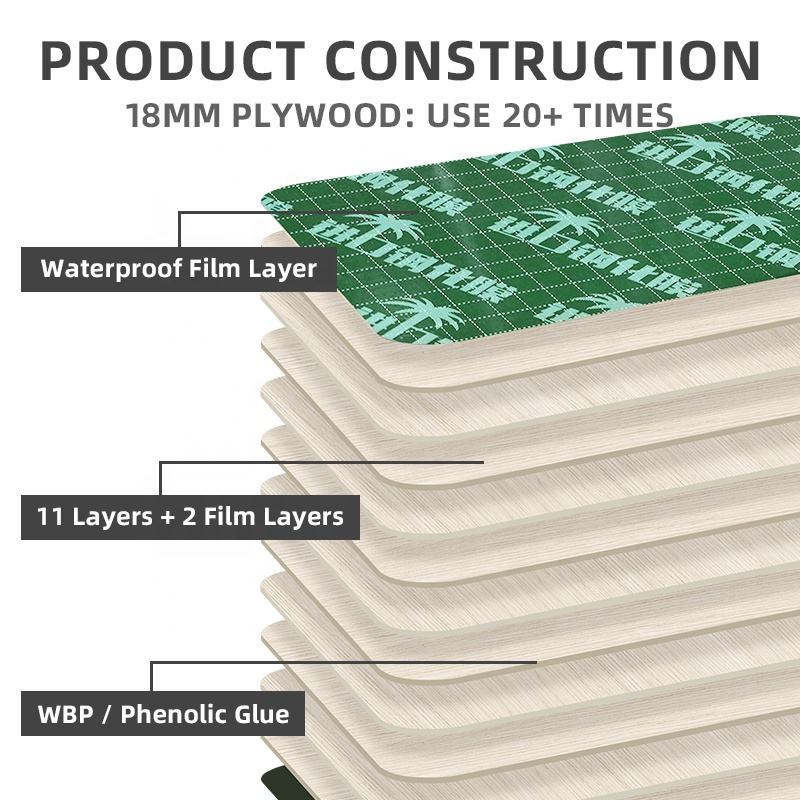

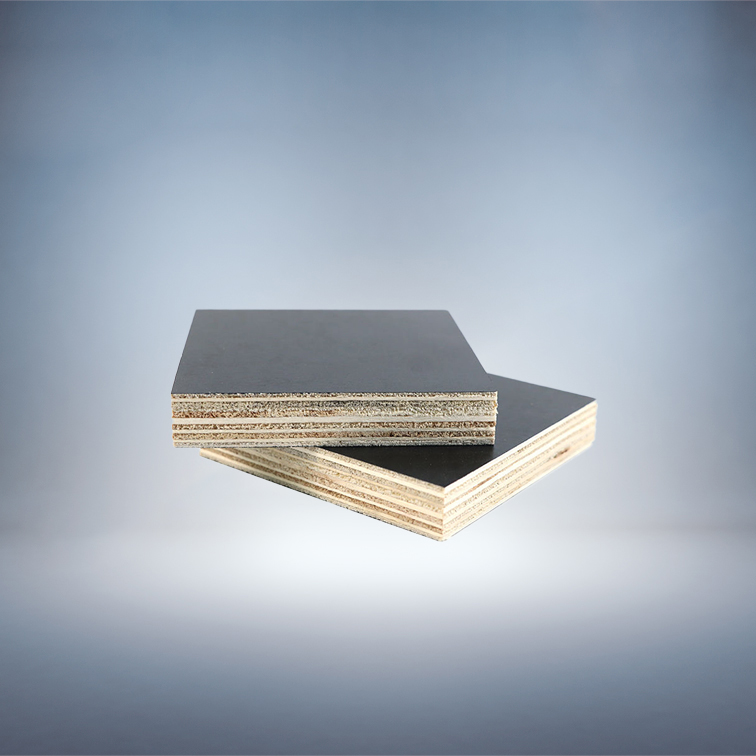

The Ultimate Upgrade: Long-Life PP Coated Plywood Our PP Membrane Plywood represents the next generation of construction formwork. By bonding a durable 0.5mm Polypropylene (PP) plastic layer to a high-density hardwood or poplar core, we have created a shuttering board that significantly outperforms traditional phenolic film-faced plywood. Engineered for demanding construction sites, this board offers exceptional wear resistance, water repellency, and a high reuse rate, making it the most cost-effective solution for large-scale concrete projects and scaffolding systems.

Description

Why Choose PP Membrane Plywood?

As a specialist in scaffolding and formwork solutions, we understand that “cost per use” matters more than the initial sheet price. Our PP Plywood is designed to lower your overall project budget through durability and efficiency.

Key Features & Advantages:

-

Superior Wear & Impact Resistance: The PP surface is highly resistant to scratches and abrasion. Unlike standard black/brown film, the PP coating does not crack easily, protecting the wood core from moisture ingress.

-

High Turnover Rate (30+ Times): Depending on the core quality and site maintenance, our PP plywood can be reused 25 to 30+ times, far exceeding the lifespan of standard film-faced plywood.

-

Perfect Concrete Finish: The smooth, hydrophobic PP surface ensures easy demoulding without the need for release agents. It produces a glossy, “fair-faced” concrete finish (Class A), reducing secondary plastering work.

-

Waterproof & Weatherproof: Combined with WBP (Water Boiled Proof) Melamine or Phenolic glue, the board is structurally stable in wet environments. The plastic face acts as a permanent barrier against rain and concrete moisture.

-

Easy to Clean & Repair: Concrete does not stick to Polypropylene. The surface can be easily cleaned with water, and the plastic layer makes the board recyclable and eco-friendlier.

Applications

-

High-Rise Building: Ideal for repetitive formwork systems (wall, column, and slab).

-

Civil Engineering: Bridges, tunnels, and dam construction requiring high load-bearing capacity.

-

Scaffolding: Durable decking and walkways.

Technical Specifications

| Property | Specification |

| Product Name | PP Membrane Plywood / PP Plastic Faced Plywood |

| Surface Material | 0.5mm – 0.7mm Polypropylene (PP) Plastic |

| Surface Finish | Smooth / Matt / Anti-slip |

| Core Material | Poplar, Eucalyptus, Combi, Birch, or Finger-joint |

| Glue Type | Melamine WBP / Phenolic WBP (72 hours boil test) |

| Size | 1220x2440mm (4×8′), 1250x2500mm, or customized |

| Thickness | 12mm, 15mm, 18mm, 21mm |

| Reuse Times | 15 – 30+ times (depending on usage) |

| Moisture Content | 8% – 12% |