Mastering Heavy-Duty Bridge Construction: Why Ringlock Scaffolding & Film Faced Plywood Are Essential

The Backbone of Modern Infrastructure Bridge construction demands uncompromising safety and extreme load-bearing capabilities. As seen in our recent project photos, the complexity of cast-in-situ concrete bridges requires a support system that is not only robust but also adaptable. This is where our premium construction materials make the difference.

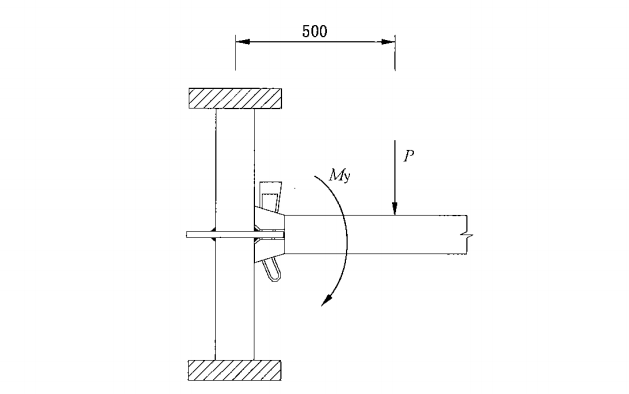

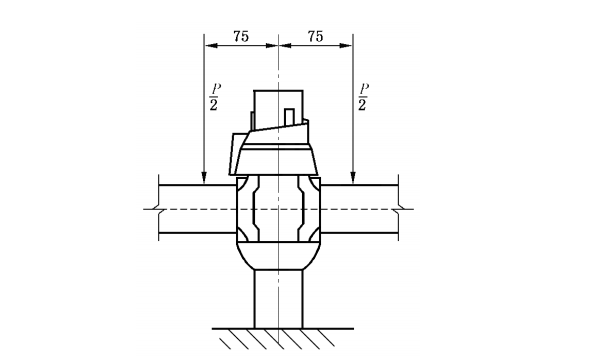

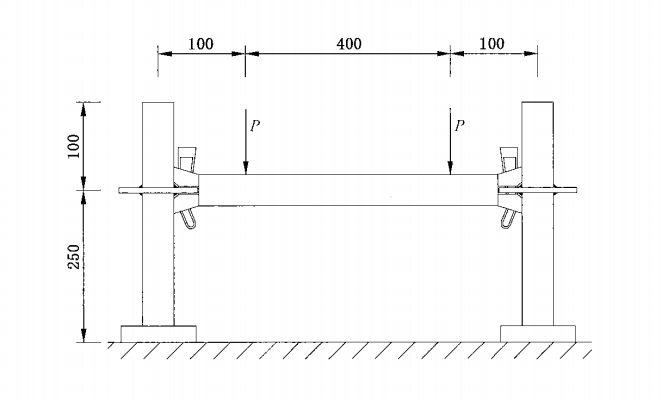

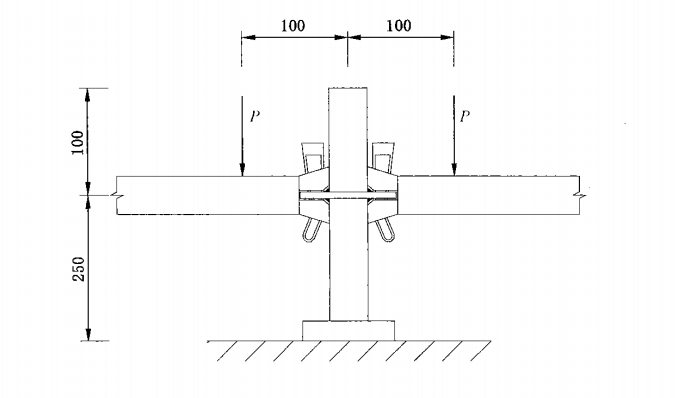

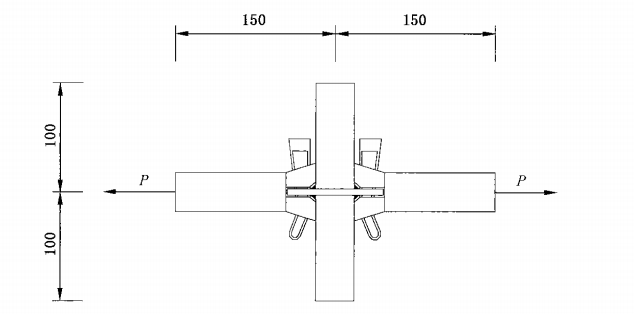

The Power of Ringlock Scaffolding in Bridge Engineering Our Ringlock Scaffolding system is the hero of heavy-duty shoring.

-

High Load Capacity: Engineered to support the immense weight of wet concrete and steel reinforcement in bridge decks.

-

Stability: The unique rosette connection provides rigid multi-directional support, ensuring structural integrity even under high stress.

-

Durability: Hot-dipped galvanized finishing ensures resistance to corrosion, vital for projects exposed to wet curing conditions (as shown in the site photos).

Ringlock under flowing water

Achieving the Perfect Finish with Film Faced Plywood Beneath every perfect concrete surface lies high-quality formwork. Our Film Faced Plywood offers:

-

Smooth Surface: Creates a fair-faced concrete finish, reducing the need for secondary plastering.

-

Water Resistance: High-quality phenolic glue prevents delamination, even during the water-intensive curing process.

-

High Reuse Rate: Durable enough to withstand multiple cycles, lowering project costs.

Versatile Support with Steel Props For areas requiring flexible height adjustment and focused load support, our adjustable Steel Props provide the perfect complement to the main scaffolding structure, ensuring precision in leveling.

Why Choose Us? Global Reach, Local Solutions We don’t just sell products; we offer solutions. From material calculation to logistics, we export globally to support infrastructure projects of any scale.

-

One-Stop Sourcing: Scaffolding, Formwork, and Accessories.

-

Expert Consultation: Tailored proposals for your specific project needs.

-

Global Export: Reliable shipping to any port in the world.

Call to Action: Ready to elevate your next construction project? Contact our team of experts today for a customized quote and solution proposal.