How to Extend Scaffolding Pipe Lifespan: ROI Analysis of Straightening Machines

In the highly competitive construction industry, material cost control is often the difference between a profitable project and a breaking-even one. For scaffolding rental companies and large-scale contractors, steel pipes are assets, not consumables.

However, on every job site, scaffolding tubes suffer from bending, rust corrosion, and hardened concrete adhesion. Discarding these pipes is a massive waste of capital.

As a scaffolding and formwork solution specialist, I often get asked: “Is it worth investing in a pipe straightening machine?” Today, let’s break down the math and look at how automated maintenance extends material lifespan and boosts your bottom line.

The Hidden Cost of Neglected Pipes

Before we look at the solution, let’s analyze the problem. Damaged scaffolding pipes create three major issues:

-

Safety Risks: Bent pipes compromise the structural integrity of the scaffold.

-

Increased Labor: Manual cleaning of concrete is slow, labor-intensive, and often ineffective.

-

Shortened Lifespan: Rust eats away at the wall thickness, rendering the pipe useless within a few years.

The Solution: 3-in-1 Automated Restoration

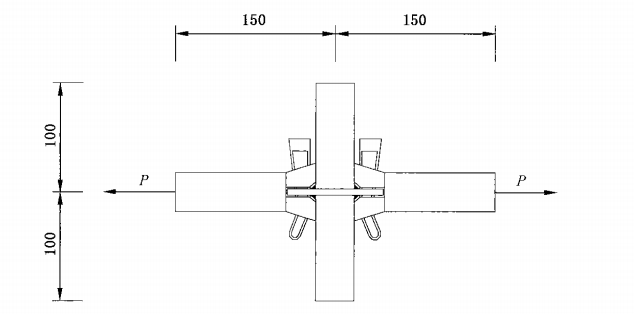

A professional Steel Pipe Straightening Machine (often called a Scaffolding Tube Restorer) tackles these problems simultaneously. It is designed to perform three functions in a single pass:

-

Straightening: Hydraulic rollers correct bends instantly.

-

Descaling/Cleaning: Mechanical brushes remove concrete crusts and rust.

-

Painting: An automated coating system applies anti-rust paint to prevent future corrosion.

The ROI Analysis: Does the Machine Pay for Itself?

Let’s look at a hypothetical scenario based on current global market averages (Estimates for reference).

Scenario: A rental company has 10,000 meters of damaged/dirty pipes in the yard.

-

Cost of Purchasing New Pipes: Approx. $3.50 – $5.00 per meter.

-

Replacement Cost: $35,000 – $50,000.

-

-

Cost of Restoration (Using Machine):

-

Machine Cost (Amortized): Minimal per meter.

-

Labor & Electricity & Paint: Approx. $0.20 – $0.30 per meter.

-

Total Restoration Cost: $2,000 – $3,000.

-

💡 The Result:

By restoring instead of replacing, you save over 90% of the material cost. If the machine processes 15 meters per minute, you can restore thousands of meters in a single week. For most mid-sized companies, the machine achieves ROI (Return on Investment) within the first 1-2 months of operation.

Beyond Cost: Branding and Professionalism

Using a Scaffolding Straightening and Rust Removal Machine isn’t just about saving money; it’s about your brand image.

-

For Rental Companies: Delivering clean, straight, and freshly painted pipes allows you to command higher rental rates and builds trust with clients.

-

For Contractors: It demonstrates a commitment to safety and equipment quality.

Conclusion

To stay competitive in the global construction market, you need smart solutions. Don’t let your profits rust away in the scrap yard. Turning waste into brand-new assets is the hallmark of modern construction management.

Looking for a high-efficiency scaffolding maintenance solution? We offer heavy-duty straightening machines tailored to your site’s needs.

👉 Contact us today for a catalog and a personalized ROI calculation.Contact us