Ringlock vs. Kwikstage: The Ultimate Technical Comparison for Your Construction Project (2026 Edition)

The Dilemma of Choice .In the competitive world of construction, choosing the right scaffolding system is not just about “getting off the ground”—it’s about project timelines, labor costs, and, most importantly, safety. Two of the most dominant modular systems in the global market are Ringlock and Kwikstage.

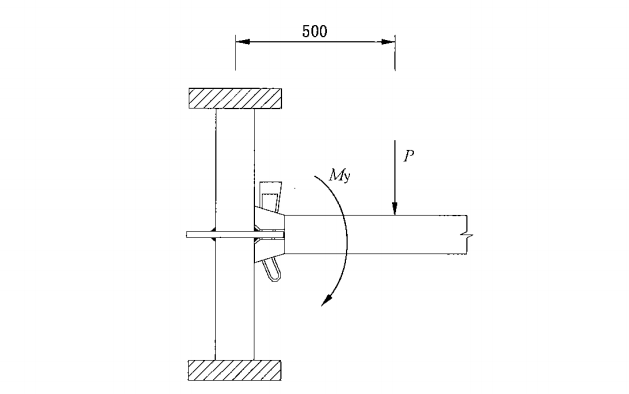

Ringlock scaffolding rosette connection detail

While both offer modularity and durability, they serve different engineering needs. As a leading Scaffolding & Formwork Solution Expert, we often get asked: “Which one is better?” The answer lies in the specific demands of your project.

1. The Ringlock System: The Modern Standard for Flexibility

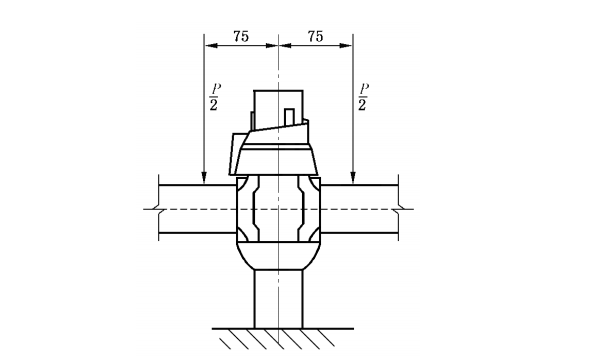

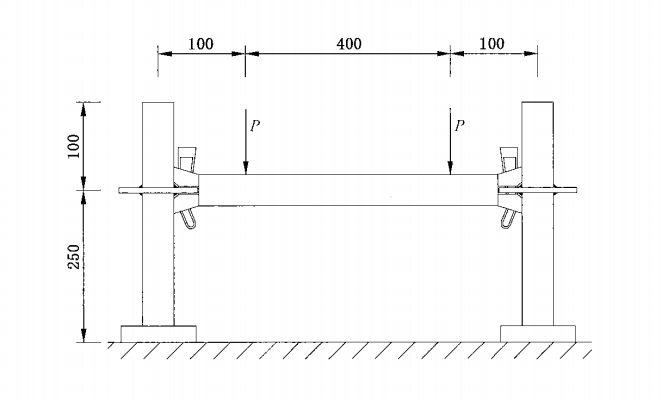

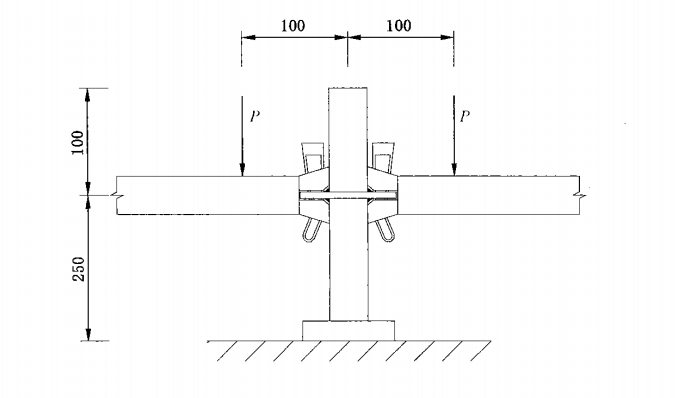

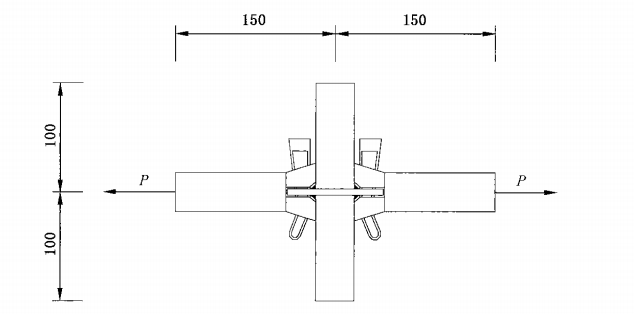

Ringlock (often called the “All-round” system) is known for its rosette connector.

-

The Mechanism: A central rosette allows up to 8 connections at various angles.

-

Best For: Complex geometries, industrial plants, offshore projects, and circular structures.

-

Pros:

-

Unmatched Flexibility: The 360-degree connection capability makes it superior for odd-shaped buildings.

-

High Load Capacity: The vertical alignment of the ledger and diagonal brace creates a rigid structure ideal for heavy-duty shoring.

-

Safety: The wedge-lock system prevents loose components from falling.

-

2. The Kwikstage System: The King of Speed and Simplicity

Originating in the UK and Australia, Kwikstage uses a “wedge” fixing system.

-

The Mechanism: A V-pressing on the standard and a wedge on the ledger lock together.

-

Best For: Straight facades, residential housing, and simple formwork support.

-

Pros:

-

Fast Assembly: “Kwik” by name, quick by nature. The system has fewer loose parts, reducing assembly time for straightforward grids.

-

Simplicity: Easier for less experienced labor to erect on simple square/rectangular layouts.

-

Robustness: Highly durable in rough site conditions.

-

3. Head-to-Head Comparison

| Feature | Ringlock System | Kwikstage System |

| Flexibility | ⭐⭐⭐⭐⭐ (High – 8 connection points) | ⭐⭐⭐ (Medium – 4 connection points) |

| Load Bearing | Excellent (Ideal for heavy shoring) | Good (Standard construction) |

| Assembly Speed | Fast | Very Fast (For simple structures) |

| Storage/Transport | High efficiency (stackable) | Moderate (can be bulky) |

| Cost | Higher initial investment | Generally lower initial cost |

4. The Expert Verdict: ROI Analysis

-

Choose Ringlock if: Your project involves complex architecture, requires high load-bearing capacity (like bridge construction), or if you are a rental company looking for a system with the highest long-term resale value and versatility.

-

Choose Kwikstage if: You are working on standard residential or commercial facades with straight lines, and your priority is speed and simplicity for a specific budget.

Conclusion: Partner with a Solution Expert

Equipment is only 50% of the solution; the other 50% is the strategy. At Metenique, we don’t just sell steel; we provide comprehensive scaffolding solutions. Whether you need the precision of Ringlock or the speed of Kwikstage, we offer high-quality manufacturing, rust-prevention technology, and global logistics.

🚀 Ready to optimize your project?

[Contact Us Today for a Free Consultation & Quote]