Why Single-sided Shear Strength of Scaffolding Rosettes is Critical for Site Safety

In a Ringlock scaffolding system, the rosette is not just a connection point; it is the “heart” of the entire support system. Today, we will delve into a key industry metric for measuring connection reliability: the single-sided shear resistance test of the rosette.

What is Single-sided Shear Resistance?

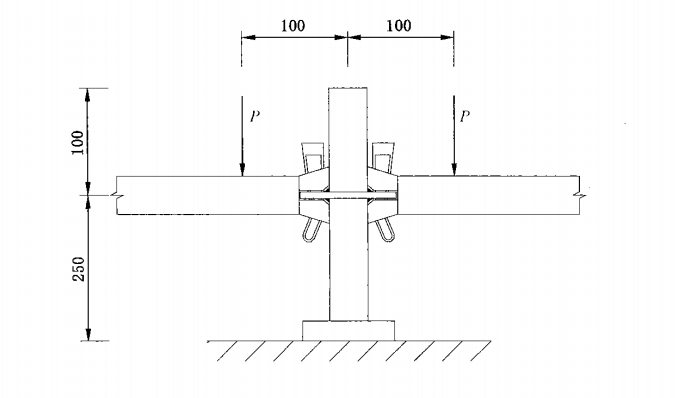

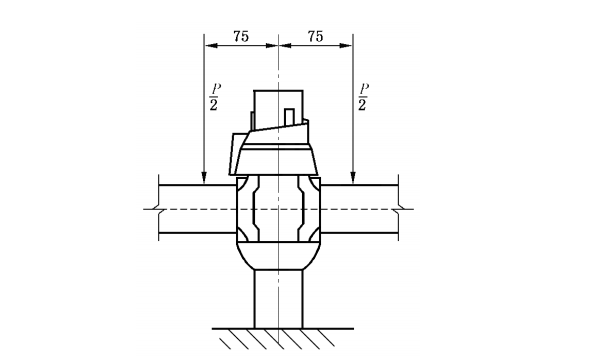

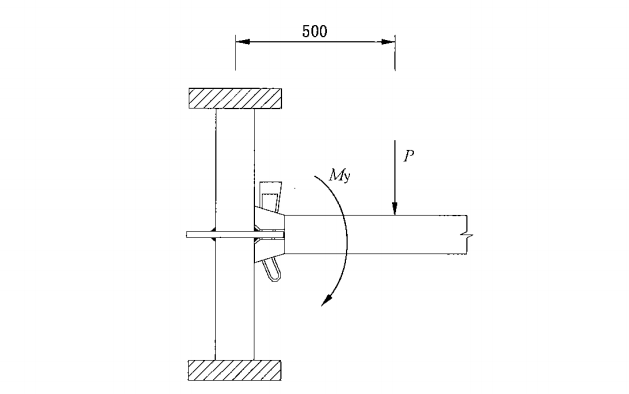

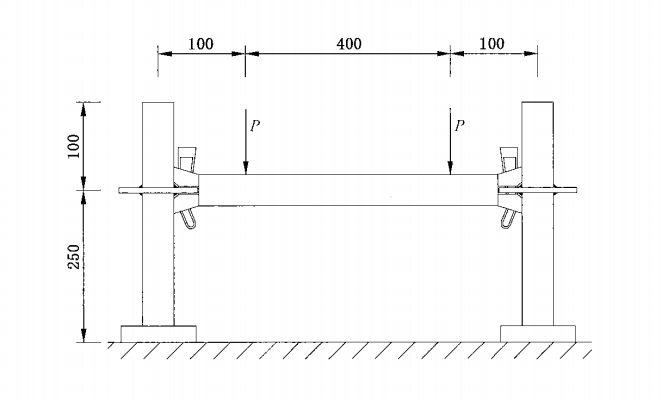

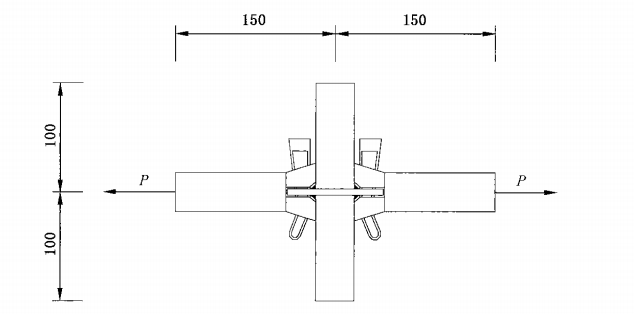

In actual construction, the loads on scaffolding ledgers are often asymmetrical. The single-sided shear strength test simulates the most extreme scenario: where the load is applied to only one side of the connection plate.

Professional Definition: This test measures the maximum shear force a single rosette-to-ledger joint can withstand without failure or excessive deformation when a vertical load is applied.

Testing Standards & Methodology

To ensure the global compliance of our exported products, we strictly adhere to EN 12811-3 or ANSI/SSFI SC100-5/05 standards:

Testing Equipment: A high-precision universal testing machine is used.

Loading Method: A vertical downward load is applied, and the relationship curve between displacement and force is recorded.

Key Metrics:

Yield Strength: The point at which the connection begins to undergo permanent deformation.

Ultimate Load: The maximum value before the connection completely fails.

Single-sided Shear Strength of the Rosette-to-Ledger Joint

Why Buyers Should Care?

As a visitor to our website or a potential distributor, understanding this data can provide you with the following benefits:

Reduced Legal Risks: Ensuring your project complies with stringent European and American safety audit standards.

Extended Service Life: High shear strength connecting plates resist deformation after multiple assembly and disassembly cycles, improving refurbishment rates (this is why our straightening machines and materials complement each other).

Support for Heavy-Duty Construction: Suitable for specialized engineering projects with high load requirements, such as bridges and tunnels.

Global Export & Dealer Support

We not only provide high-quality ringlock and cuplock scaffolding systems and accessories, but also offer comprehensive technical reports and engineering calculation support.

Worldwide shipping available.

OEM/ODM customized production.

Regional distributors wanted.