Ringlock Scaffolding: How Does It Achieve a Win-Win of High Efficiency and Absolute Safety?

In the highly competitive construction industry, time is money, and safety is paramount. Project managers are constantly seeking solutions that enhance efficiency while ensuring safety. Ringlock Scaffolding (Modular System Scaffolding) is precisely such a modern solution that delivers a “win-win.” It not only redefines construction speed but also sets a new benchmark for on-site safety.

I. Unmatched Construction Efficiency Drastically Shortens Project Timelines

The core design philosophy of Ringlock Scaffolding is “efficiency.”

-

Lightning-Fast Installation & Dismantling:

-

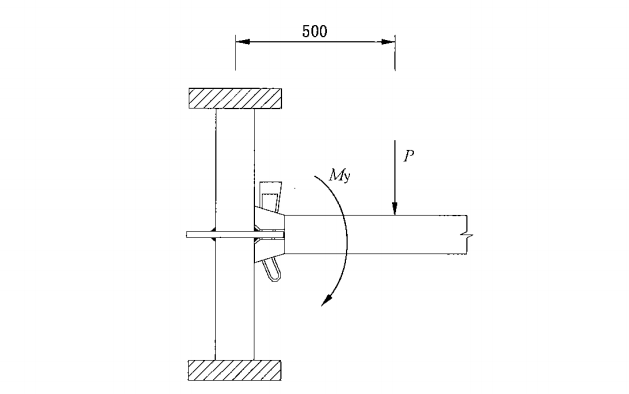

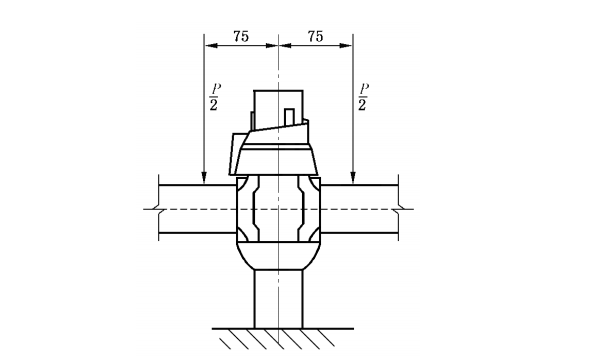

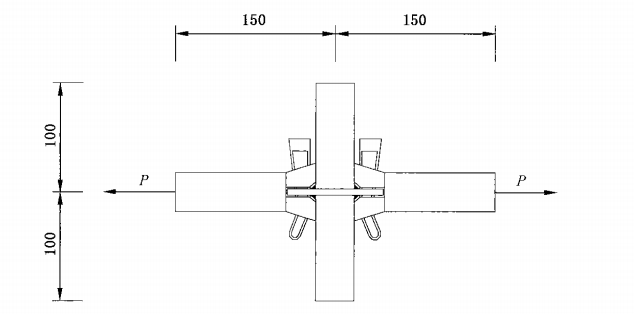

Unique Wedge-Lock System: All connections are made via a drop-forged blade and wedge. Workers need no tools—just a hammer—to secure a robust connection. A simple “insert and tap” action replaces the tedious process of tightening bolts and couplers in traditional scaffolding, increasing speed by up to 300%.

-

“LEGO-Like” Simplicity: Components are highly standardized. Workers can become proficient after minimal training. This intuitive assembly method greatly reduces the technical threshold and human error rate, ensuring each tier is erected quickly and accurately.

-

-

Modularity & Systematic Management:

-

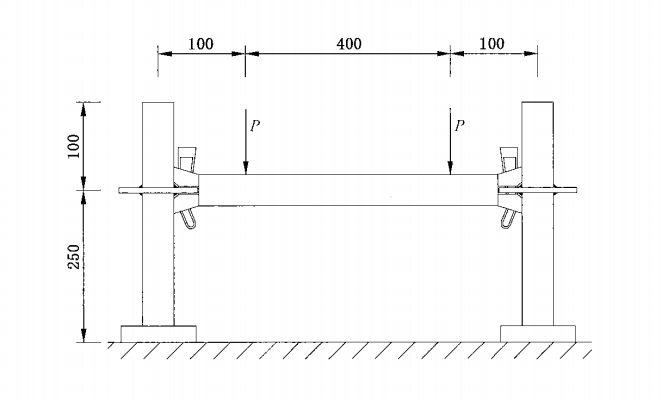

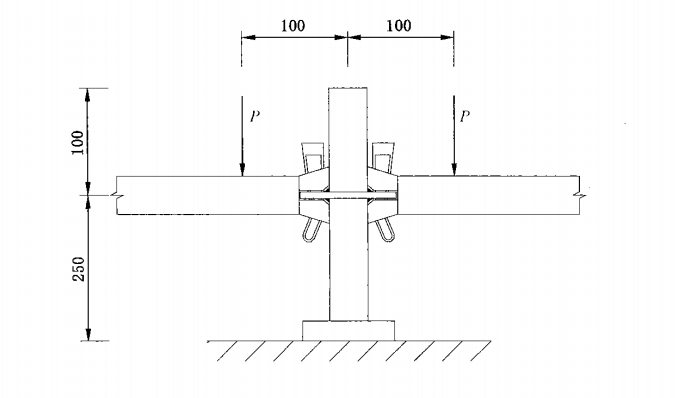

Ringlock Scaffolding is a complete system. Standards, ledgers, braces, and various accessories (like stairways and platforms) follow unified modules with excellent compatibility. This not only keeps the site tidy but also minimizes part loss. All components can be quickly counted, transported, and deployed to the next project, saving significant time across the entire project lifecycle.

-

II. Built-In Superior Safety Safeguards Efficient Construction

High efficiency without the foundation of safety is a house of cards. Ringlock Scaffolding has safety embedded in its DNA.

-

Revolutionary Structural Stability:

-

The unique rosette (cup) connection node provides multi-directional rigid support, transforming the entire structure into a solid “steel module.” Its load-bearing capacity far exceeds that of traditional scaffolds, effectively resisting sway and deformation during construction and providing a solid, reliable working platform.

-

-

Eliminating Human Error at the Source:

-

The wedge mechanism tightens under load, and the connection’s integrity is visually verifiable, making it resistant to loosening due to oversight. This fundamentally reduces the risk of collapse due to insecure joints—an advantage unmatched by traditional bolts that rely on a worker’s “feel” for tightness.

-

-

An Ideal Platform for Safety Protection:

-

The systematic design allows for compatible steel platforms, safety staircases, guardrails, and toe boards to be easily and securely attached. It creates an intrinsically safe work environment, proactively preventing falls from height and falling object strikes.

-

III. The Synergy of High Efficiency and High Safety: Creating Real Value

When construction speed is enhanced by Ringlock Scaffolding, you save not only on labor costs but also on precious project timelines. When safety risks are minimized due to its exceptional stability, you avoid not only potential loss of life and property but also the massive domino effect of project delays.

Conclusion

Choosing Ringlock Scaffolding is a strategic decision that enhances your project’s overall competitiveness. It is not merely a material substitution but an upgrade from outdated construction methods. It transforms the dilemma of choosing between “faster” and “safer” into an achievable dual goal, ultimately helping you shorten project duration, reduce costs, and build a professional reputation.