Unlocking Stability: The Ringlock Rosette Bending Moment Resistance Test (EN 12811) | FormScaffold

Beyond Vertical Load: Why Joint Stiffness Defines Scaffolding Safety

When evaluating scaffolding quality, most buyers focus on Vertical Shear Strength (how much weight it can hold). While critical, this is only half the story.

If you have ever stood on a tall scaffolding tower that felt “wobbly” or “loose,” the issue wasn’t likely the steel grade—it was the Joint Stiffness.

At FormScaffold, we position ourselves not just as a manufacturer, but as a structural safety partner. Today, we are releasing the technical footage of our Rosette Bending Moment Resistance Test, conducted in accordance with EN 12811-3.

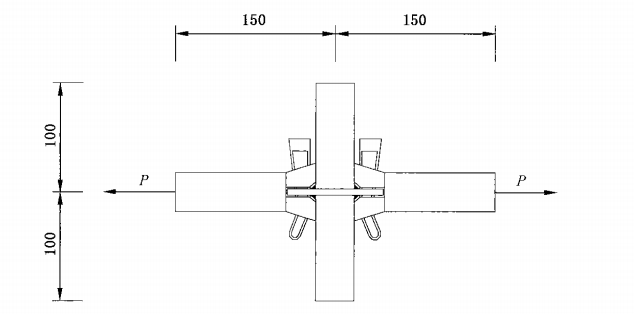

Measuring the rotational stiffness and moment resistance of FormScaffold Ringlock connections

What is the Bending Moment Test?

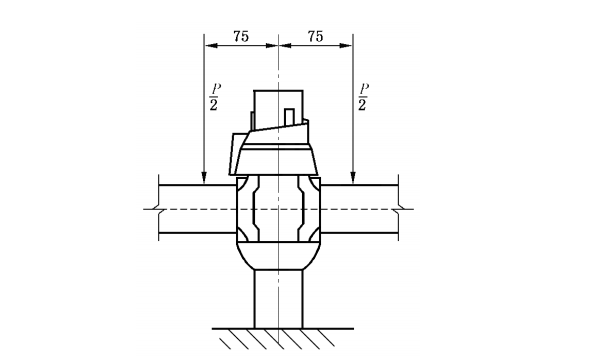

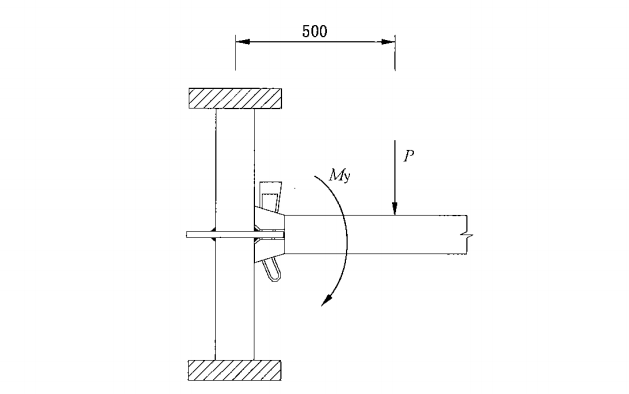

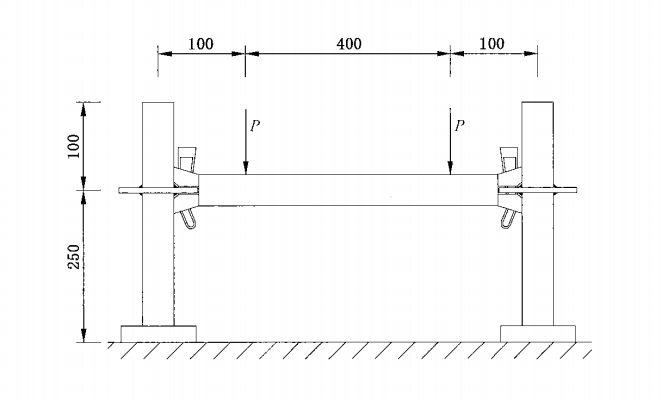

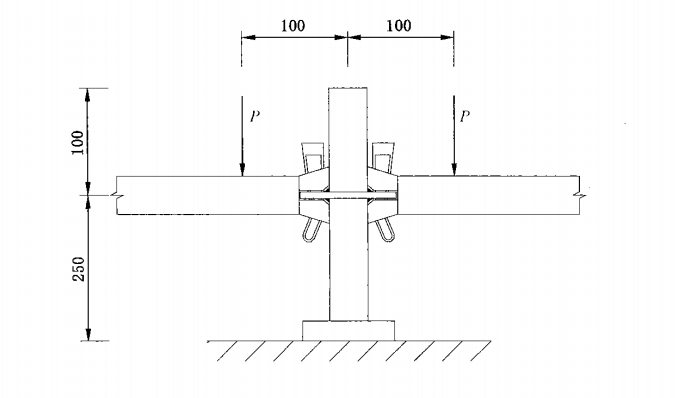

In a Ringlock system, the wedge connects the ledger to the rosette. When wind loads or cantilevered loads are applied, the connection tries to rotate.

This test measures two critical engineering parameters:

-

Moment Resistance : The maximum torque the joint can withstand before failure.

-

Rotational Stiffness: How rigidly the ledger is locked to the rosette.

Why High Stiffness Matters for Your Project

A “rigid” connection acts more like a welded joint and less like a hinge. High stiffness brings tangible benefits to your construction site:

-

Reduced Sway: Significantly minimizes lateral movement in high-rise facades.

-

Optimized Design: Engineers can often reduce the number of diagonal braces needed in specific designs, saving material costs.

-

Cantilever Safety: Essential for suspended platforms or bridge overhangs where bending forces are extreme.

The FormScaffold Difference

As seen in the video, our high-precision casting and wedge design ensure a tight, secure fit. The load-displacement curve from our lab confirms that our nodes maintain high rigidity even under significant stress, far exceeding standard safety factors.

Conclusion:

Don’t just buy steel; buy stability. When you choose FormScaffold, you are choosing a system that has been engineered to stand firm.

Planning a complex project?

Our engineering team can assist with load calculations and layout designs based on our certified test data.

[> Contact Our Engineering Team] [> View Ringlock System Specifications]