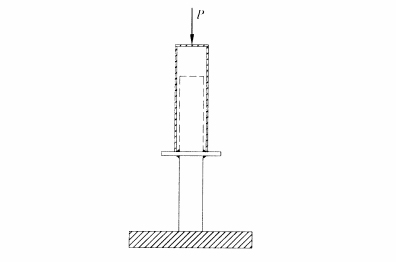

In the construction industry, safety is not just a requirement; it is the foundation of every successful project. As a professional Ringlock scaffolding manufacturer, we understand that the strength of the entire system relies on the quality of its smallest components. Recently, our Quality Control (QC) team conducted a rigorous Internal Weld Shear Test on [...]

In the UK, the weather is often a contractor's biggest adversary. Heavy rainfall and high winds not only cause the initial roof damage (leaks, loose tiles) but also make the repair process notoriously difficult. For scaffolding companies and contractors, standard access isn't enough. You need a weather-resilient access solution. As experts in formwork and scaffolding [...]

In the highly competitive construction industry, material cost control is often the difference between a profitable project and a breaking-even one. For scaffolding rental companies and large-scale contractors, steel pipes are assets, not consumables. However, on every job site, scaffolding tubes suffer from bending, rust corrosion, and hardened concrete adhesion. Discarding these pipes is a [...]

The Dilemma of Choice .In the competitive world of construction, choosing the right scaffolding system is not just about "getting off the ground"—it’s about project timelines, labor costs, and, most importantly, safety. Two of the most dominant modular systems in the global market are Ringlock and Kwikstage. Ringlock scaffolding rosette connection detail While [...]

The Foundation of Safety Introduction: The Hidden Cost of Cheap Steel In the construction industry, scaffolding is the lifeline of your workforce. When sourcing scaffolding from China, many buyers focus solely on the "price per ton," overlooking the critical factor that dictates safety and longevity: the Raw Material. As a leading expert in formwork and [...]

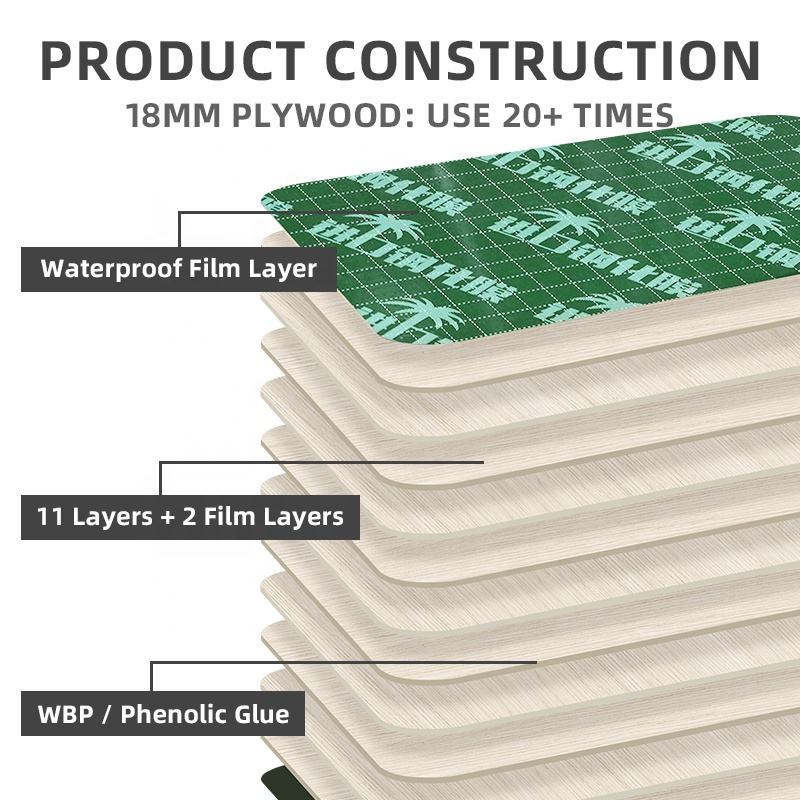

In the competitive world of construction and formwork, the initial price tag often dictates the purchase decision. But ask any veteran site manager: The cheapest sheet is often the most expensive one in the long run. Today, we compare the rising star—PP (Polypropylene) Membrane Plywood—against the traditional Phenolic Film Faced Plywood. Is the upgrade worth [...]