Efficiency in Extreme Environments: Optimizing Oil and Gas Energy Equipment Maintenance with Advanced Access Solutions

Introduction: The High Stakes of Maintenance In the oil and gas sector, asset integrity is non-negotiable. Whether it is an upstream offshore rig or a downstream refinery, the efficiency of your maintenance turnaround directly impacts your bottom line. Central to this process is the often-overlooked backbone of industrial repair: the access system. Today, we analyze how integrating high-grade ladders and scaffolding with modern aerial work platforms forms a critical part of effective energy management solutions.

Aerial work platform maintenance

1. The Evolution of Oil and Gas Energy Equipment Access Traditional access methods are facing new scrutiny. The complex geometry of modern refineries and the harsh corrosive environment of offshore sites demand more than just standard tubes and clamps.

-

Modular Efficiency: Modern scaffold platforms, such as Ringlock systems, are essential. Their modular design allows for rapid assembly around irregular piping and vessels, reducing the man-hours required for setup and dismantling by up to 30%.

-

Material Durability: For oil and gas energy equipment exposed to saltwater and chemicals, hot-dip galvanized steel is the industry standard, ensuring structural integrity and safety compliance (OSHA/EN standards).

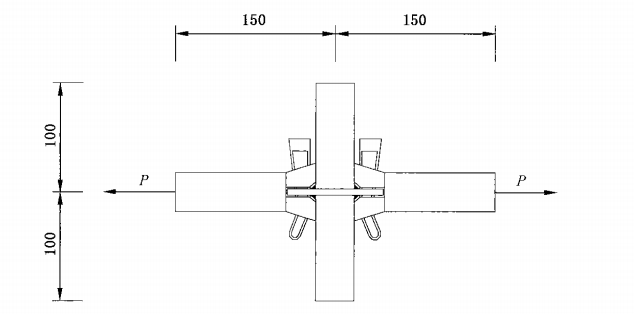

2. Aerial Work Platforms: Speed Meets Safety While scaffolding provides a fixed workspace for long-term repairs, the aerial work platform (AWP) is the champion of agility.

-

Rapid Inspection: For sensor calibration, valve checks, or insulation repair, deploying a boom lift or scissor lift eliminates the need for time-consuming scaffold erection.

-

Precision Access: Modern AWPs offer precise positioning in tight spaces, allowing technicians to reach critical components without disrupting surrounding infrastructure. This agility is a key component of modern energy management solutions, minimizing operational pauses.

3. Decoding the True Scaffolding Cost Procurement managers often focus on the upfront rental or purchase price—the visible scaffolding cost. However, the “Total Cost of Ownership” tells a different story.

-

Labor Savings: A cheaper, non-modular system may cost less to buy but requires double the labor time to erect.

-

Downtime Reduction: If a premium scaffold platform or AWP helps finish a turnaround two days early, the revenue saved from regained production far outweighs the equipment cost.

-

Safety metrics: High-quality equipment reduces accident risks, lowering insurance premiums and liability exposure.

Conclusion Optimizing maintenance in the energy sector requires a hybrid strategy. By selecting the right combination of heavy-duty ladders and scaffolding for major overhauls and agile aerial work platforms for quick tasks, companies can significantly improve operational efficiency.

At Metenique, we provide certified access solutions engineered for the rigorous demands of the oil and gas industry.

Call to Action: Ready to optimize your next project? Contact our team for a consultation on maximizing safety and minimizing costs with our specialized access equipment.