Global Scaffolding Material Standards & Requirements: A Comprehensive Guide for Professional Builders

In the global construction industry, scaffolding is more than just a support structure; it is the foundation of safety and efficiency. Different regions have stringent standards for materials, strength, and design due to varying climates and regulations. As a specialized scaffolding manufacturer and solution expert, FormScaffold is committed to providing customized solutions that meet the highest international standards.

European standards are among the most widely adopted globally, especially for Ringlock and Cuplock systems.

-

EN 12810/12811: Defines performance requirements and structural design for system scaffolding.

-

BS 1139: The British standard specifies dimensions, wall thickness (typically 3.2mm or 4.0mm), and surface treatment (hot-dip galvanization) for tubes and couplers.

-

Key Focus: Yield strength (e.g., S235 or S355 steel) and zinc coating thickness (minimum 60μm) for corrosion resistance.

The North American market prioritizes worker safety, with standards set by ANSI and SSFI.

-

OSHA 1926.451: Focuses on safety regulations for on-site use, such as load testing (capable of supporting 4x the maximum intended load).

-

ANSI/SSFI SC100: Dictates testing methods for components, particularly the stability of Frame Scaffolding.

-

Material Specs: High-strength steel like Q345 (comparable to ASTM A572) is commonly used to meet higher load-to-weight ratios.

The Australian and New Zealand markets are known for some of the toughest requirements globally, governed by the AS/NZS 1576 series.

-

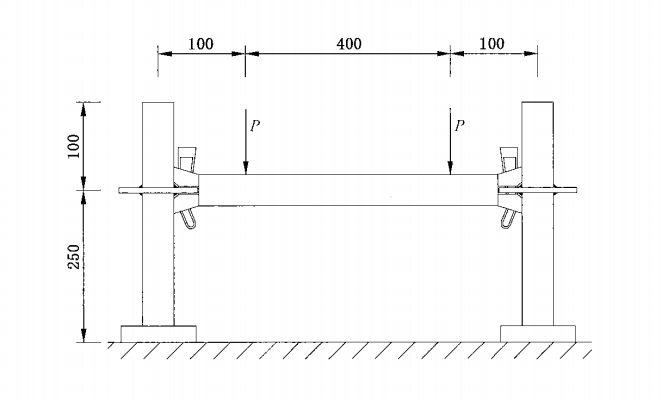

AS/NZS 1576.3: Specifically covers system scaffolding, requiring rigorous drop tests and structural load assessments.

-

Material Preferences: High-strength aluminum alloy (6061-T6) or fully hot-dip galvanized steel are preferred to withstand corrosive coastal environments.

Japanese JIS Standards: Demand exceptionally high precision in welding and component tolerances.

-

Chinese GB Standards: With technological iterations, Chinese standards for Ringlock scaffolding (like GB 50367) are now aligned with international levels, with Q355B steel becoming the mainstream for high-end export projects.

As an experienced manufacturer, FormScaffold provides compliance assurance beyond the product itself:

-

Material Traceability: We use only premium Q235/Q355 steel with Mill Test Certificates (MTC).

-

Rigorous Testing: Our in-house lab conducts regular destructive testing to ensure every batch meets target market standards (EN/ANSI/AS).

-

Customized Solutions: We provide full structural calculations and designs, from formwork support to heavy-duty shoring, tailored to specific regional safety factors.

Choosing scaffolding that complies with local standards is crucial for ensuring site safety and avoiding legal risks. Whether your project is in Europe, the Americas, or Oceania, FormScaffold offers the professional expertise you need. Contact our expert team today for your professional global project solution!