Scaffolding Solutions for UK Roof Repairs: Conquering Bad Weather & Leaks

In the UK, the weather is often a contractor’s biggest adversary. Heavy rainfall and high winds not only cause the initial roof damage (leaks, loose tiles) but also make the repair process notoriously difficult.

For scaffolding companies and contractors, standard access isn’t enough. You need a weather-resilient access solution. As experts in formwork and scaffolding manufacturing, we analyze how to optimize scaffolding for roof repairs under harsh British conditions—balancing efficiency, safety, and cost.

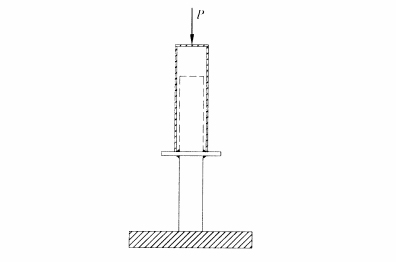

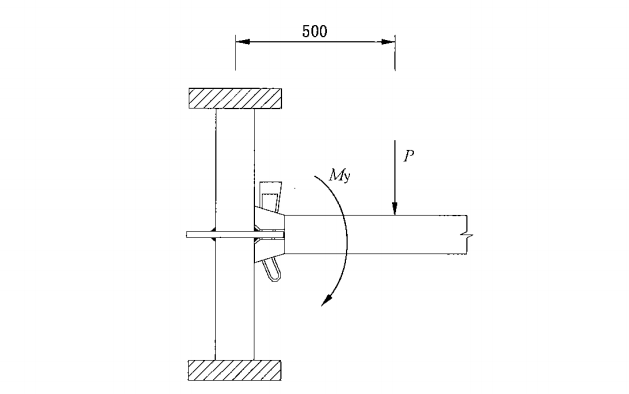

Temporary Roof of scaffolding

1. The Challenge: Why Standard Scaffolding Fails in Rain

When dealing with an emergency roof leak, time is money. However, standard tube and fitting scaffolds often face delays due to:

-

Slippery surfaces: Increasing slip and fall risks.

-

Water ingress: Rain damaging the exposed roof structure while work is in progress.

-

Wind Loading: High altitude roof work is susceptible to strong gusts.

2. The Solution: Temporary Roof Systems (The “Tin Hat”)

The ultimate mark of a professional scaffolding solution is the Temporary Roof. This involves erecting a cover over the entire working area.

-

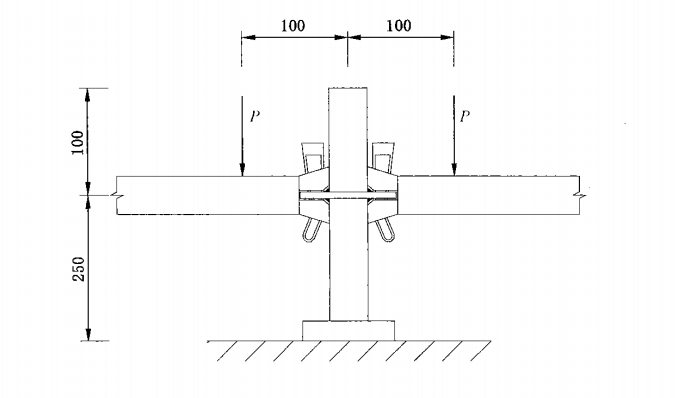

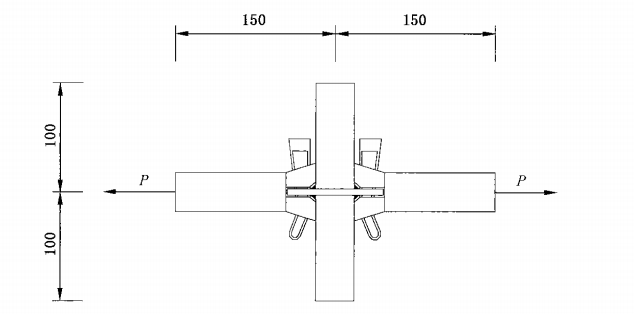

Technique: utilizing lightweight aluminum beams or truss-out systems covered with corrugated iron sheets or heavy-duty shrink wrap.

-

Benefit: It transforms a weather-dependent site into an indoor factory environment, allowing work to continue 24/7 regardless of rain.

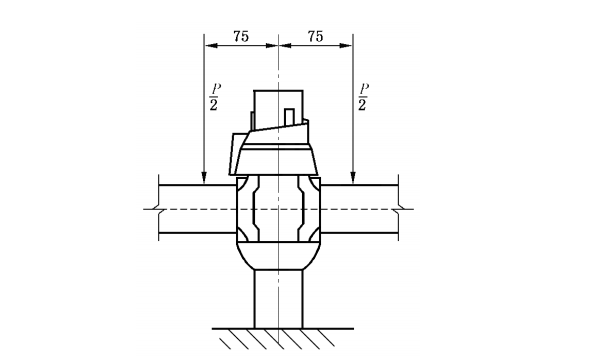

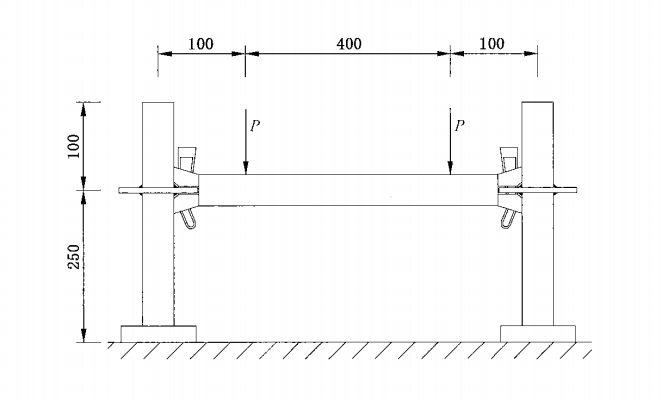

3. Efficiency: Ringlock vs. Tube & Clamp

For emergency repairs, speed is critical.

-

Traditional Tube & Clamp: Flexible but slow. Requires highly skilled labor to level every tube.

-

The Ringlock System Advantage: We highly recommend using Ringlock (Modular) Scaffolding for roof access. Its rosette connections allow for rapid erection—up to 50% faster than traditional methods.

-

Why it matters: Faster erection means the roof is accessed and covered sooner, minimizing water damage to the property interior.

4. Safety & Compliance (NASC & TG20:21)

In the UK, adherence to NASC (National Access & Scaffolding Confederation) guidelines is non-negotiable.

-

Wind Calculations: Roof access extends above the eaves, subjecting the structure to higher wind loads. Your scaffolding design must account for local wind speeds and tie patterns.

-

Guardrails: Double guardrails and toe boards are essential to prevent material from falling on pedestrians, a common risk in residential repairs.

5. Cost Analysis: Is a Temporary Roof Worth It?

Clients often hesitate at the extra cost of a temporary roof scaffold. Here is the expert breakdown:

-

Direct Cost: Higher upfront material and labor cost.

-

Hidden Savings: Prevents “rain-off” days (paying workers to sit idle). Prevents catastrophic water damage to the building interior during the repair.

-

Verdict: For extensive roof overhauls in Autumn/Winter, a weather-protection system is actually cheaper in the total project lifecycle.

Conclusion

Don’t let the British weather dictate your project timeline. By choosing the right material—specifically efficient Ringlock systems—and implementing professional temporary roofing solutions, you ensure quality and safety.

At METENIQUE, we provide high-grade scaffolding materials designed for global standards. Looking for a reliable supply chain for your next project? Contact our engineering team today for a custom solution.