Ringlock Scaffolding Safety Test: Internal Weld Shear Test on Ledger End Connector (Video Inside)

In the construction industry, safety is not just a requirement; it is the foundation of every successful project. As a professional Ringlock scaffolding manufacturer, we understand that the strength of the entire system relies on the quality of its smallest components.

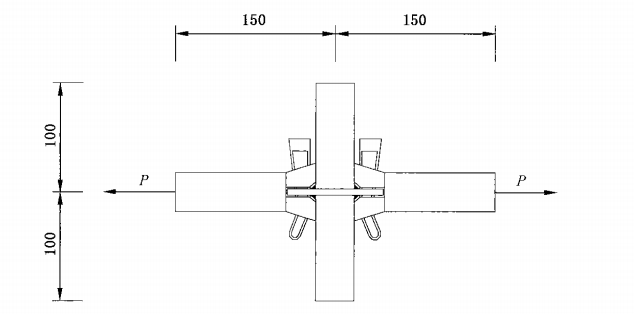

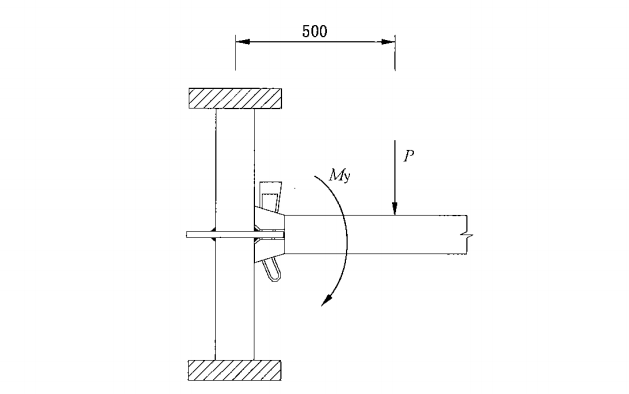

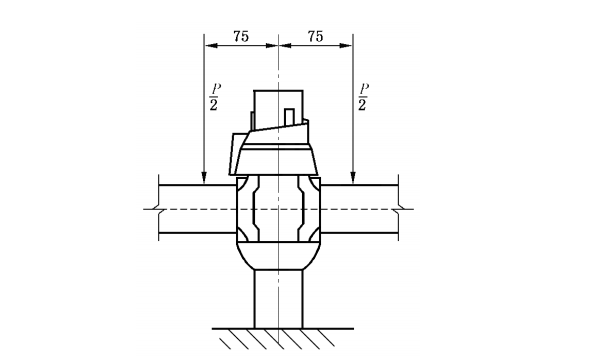

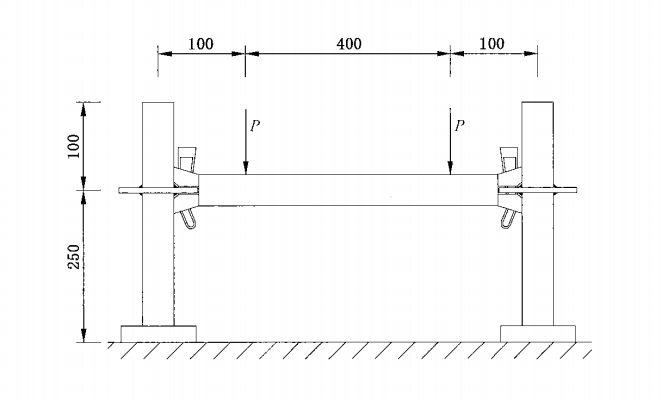

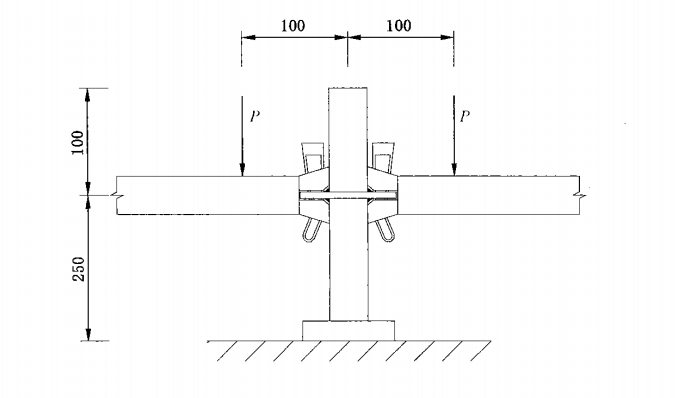

Recently, our Quality Control (QC) team conducted a rigorous Internal Weld Shear Test on our Ringlock Ledger End Connector. This component is critical for transferring loads between the ledger and the vertical standard, making its welding integrity vital for structural stability.

We recorded the entire testing process to demonstrate our commitment to transparency and international safety standards. Watch the full video below to see how our products perform under extreme pressure.

What is the Internal Weld Shear Test?

The Ledger End Connector (also known as the ledger head) is the part of the scaffolding that locks into the rosette. It bears significant weight and shear force during construction.

The Internal Weld Shear Test is designed to verify the strength of the welding inside the connector head. Unlike surface inspections, this destructive test applies force directly to the welded area to ensure it meets the load-bearing requirements specified by global standards such as EN 12810/12811 (Europe) and ANSI/SSFI (USA).

At METENIQUE, we perform this test regularly to ensure that our internal welding penetration is deep enough and strong enough to withstand heavy loads without failure.

Test Results: Zero Defects & High Load Capacity

As shown in the video, our Ledger End Connector was subjected to force exceeding standard requirements. The results were definitive:

-

Result: QUALIFIED (PASS)

-

Observation: There was no cracking, no tearing, and no deformation in the weld area.

-

Conclusion: The internal weld maintained its integrity, proving that our manufacturing process ensures maximum safety for your workers and projects.

Why Choose METENIQUE as Your Scaffolding Manufacturer?

Achieving these results is not luck; it is a result of our advanced manufacturing capabilities. Here is why contractors and distributors worldwide trust us:

-

Premium Raw Materials: We use only high-grade Q235/Q345 steel to ensure the base strength of every component.

-

Advanced Auto-Welding Technology: Our factory utilizes robotic welding systems. This ensures consistent weld height, width, and penetration depth, eliminating human error.

-

Strict Quality Control: From raw material entry to final loading, every step is monitored. We provide test reports for every batch.

Professional Scaffolding Solutions & OEM Services

We are more than just a factory; we are a scaffolding solution provider. Whether you are working on a civil engineering project, a commercial building, or an industrial plant, we offer:

-

Global Export: We have extensive experience shipping to Southeast Asia, Middle East, South America, Europe.

-

OEM & Customization: Do you have specific requirements for branding or unique specifications? We support OEM services to manufacture scaffolding according to your drawings and samples.

-

Complete Product Range: Beyond Ringlock, we also supply Frame systems, Cuplock, Kwikstage, Formwork accessories, and Steel Planks.

When it comes to scaffolding, never compromise on quality. Our successful Internal Weld Shear Test is just one example of how we prioritize safety and durability.

Are you looking for a reliable partner for your next project?

👇 Contact Us Today Get a free quote and our latest catalog. Our engineering team is ready to support your project requirements.