Cuplock Scaffolding Ledger Weld Shear Test: Exceeding BS 12811 Standards | FormScaffold

Beyond the Surface: Why We Destruction-Test Our Cuplock Ledger Welds

In the world of system scaffolding, the Cuplock System is renowned for its versatility and speed of erection. However, its safety relies heavily on one small but critical detail: The weld connecting the ledger blade (end) to the steel tube.

At FormScaffold, we believe that trust is built on data, not just promises. Today, we are sharing an inside look at our quality control process with a Shear Strength Test of our Cuplock Ledger End Welds.

Vertical Shear Strength Test on Cuplock Ledger Blade – Weld Integrity Check

The Critical Role of the Ledger Blade Weld

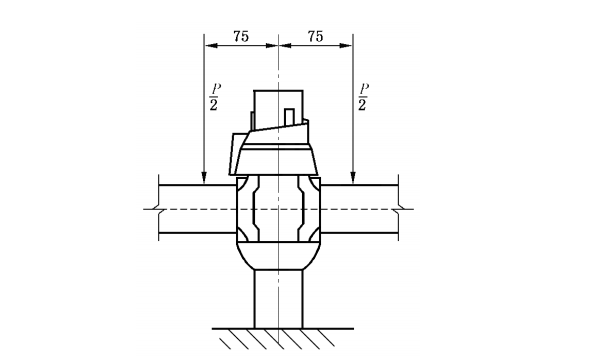

In a Cuplock system, the ledger blade is locked between the top cup and bottom cup. When the scaffold is under load (workers, concrete, materials), immense vertical shear force is applied directly to the connection point between the blade and the tube. If this weld is weak, “cold,” or shallow, it can snap without warning, leading to catastrophic structural failure.

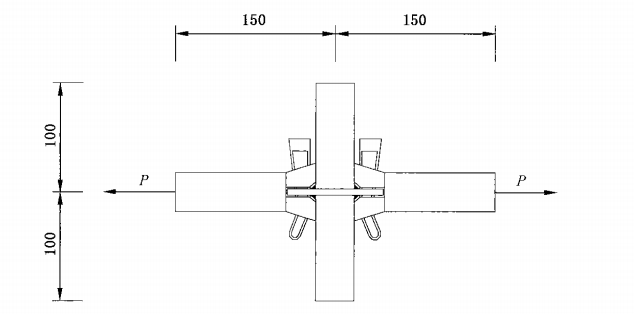

The Test Protocol

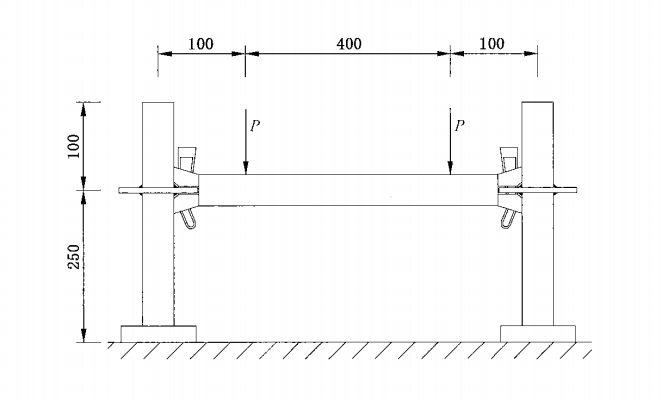

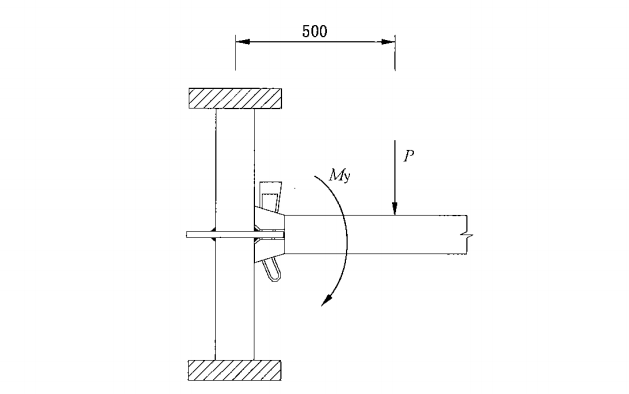

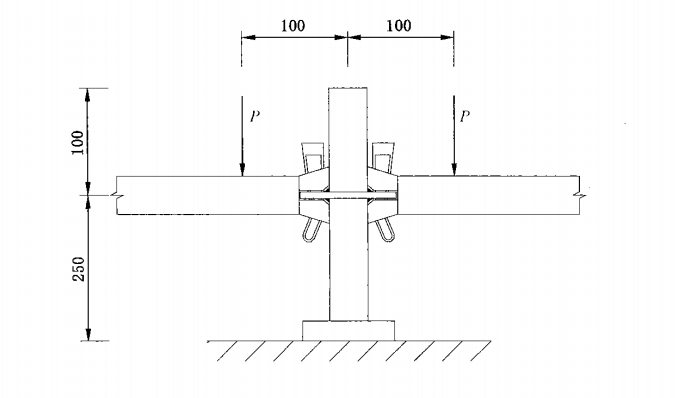

In this video, we subjected our standard Cuplock Ledger to a vertical shear load test in our laboratory.

-

Setup: The ledger blade is rigidly fixed, simulating a locked cup connection.

-

Loading: A hydraulic press applies continuous downward force to the steel tube adjacent to the weld.

-

Objective: To determine if the weld fails before the steel tube yields.

The Results: Tube Yields, Weld Holds

As seen in the footage, the steel tube begins to deform and tear under extreme pressure, while the weld seam remains intact. This result confirms that:

-

Superior Penetration: Our welding process (CO2 shielded/Robotic) achieves full penetration, fusing the blade and tube into a single structural unit.

-

Compliance: The breaking load significantly exceeds the requirements of BS 12811 and other international safety standards.

-

Consistency: By using automated welding technology, we eliminate human error, ensuring every ledger has the same high strength.

Why “Forged” Matters

It is worth noting that FormScaffold uses Drop Forged Ledger Blades (high-strength steel) rather than pressed steel. Combined with our superior welding technique, this ensures that our Cuplock system is durable enough for the harshest heavy-industry and civil engineering environments.

Partner with a Quality-First Manufacturer

Don’t gamble with safety. Whether you are in the UK, Middle East, or Africa, FormScaffold provides certified, tested, and reliable scaffolding solutions.

Need technical data or a price list? Contact our engineering team today to discuss your project requirements.

-

Q: What standard does your Cuplock welding meet?

-

A: It meets and exceeds BS 12811.