Understanding Axial Load Resistance in Ringlock Scaffolding: A Guide to EN 12811-3 & Safety

The Critical Importance of Axial Load Resistance in Ringlock Scaffolding

In the world of construction, the stability of a scaffolding system is defined by its weakest link. For the Ringlock system (Modular Scaffolding), the “heart” of this stability lies in the connection between the Rosette (Ring Plate) and the Ledger head.

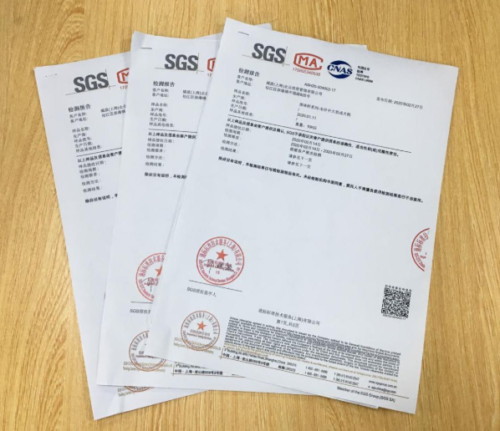

At FormScaffold, we believe that transparency builds trust. In this technical guide, we break down one of the most critical tests we perform in our factory: the Axial Load Resistance Test, based on the European Standard EN 12811-3.

What is Axial Load Resistance?

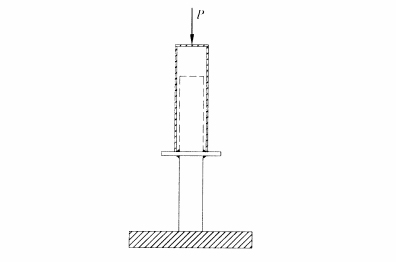

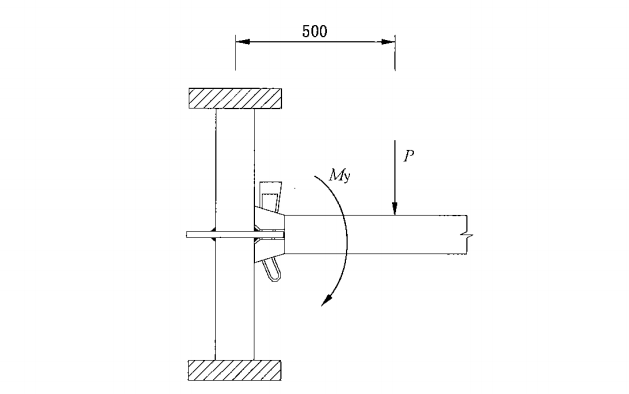

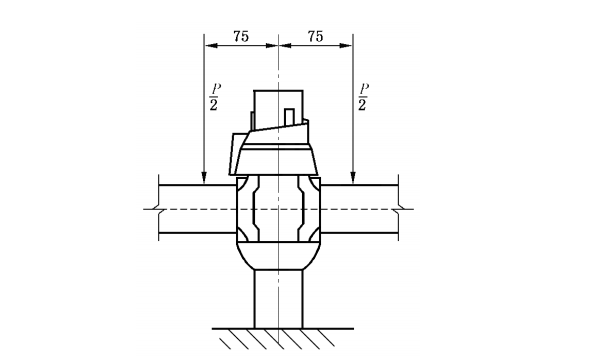

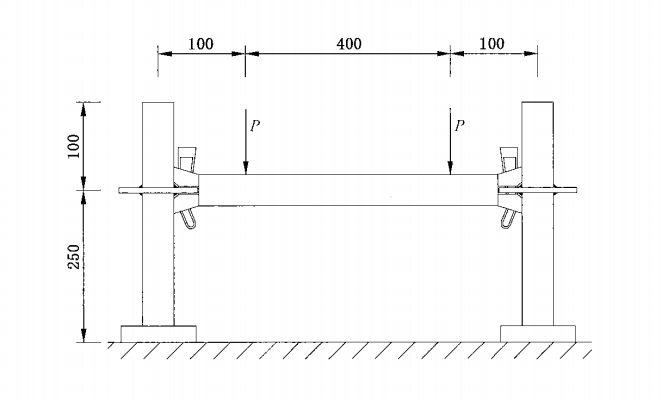

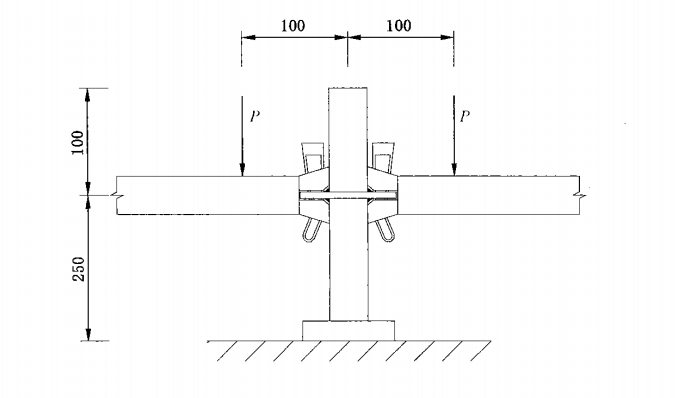

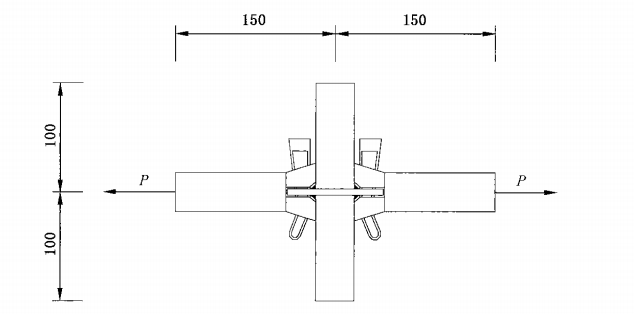

In a Ringlock system, ledgers (horizontal pipes) are connected to the vertical standards via the rosette. Axial Load Resistance measures the connection’s ability to withstand forces pulling the ledger away from the rosette horizontally.

-

Scenario: Imagine a complex heavy-duty shoring structure. Wind loads, dynamic movements, or uneven weight distribution create tension forces that try to “rip” the horizontal ledger out of the vertical node.

-

The Goal: The connection must remain rigid and not separate or deform permanently under these loads.

Decoding the EN 12811-3 Standard

EN 12811-3 (Temporary works equipment – Part 3: Load testing) is the global benchmark for testing scaffolding node stiffness and strength. It is far more rigorous than simple static load tests.

A proper EN 12811-3 test involves:

-

Hysteresis Cycles: Loading and unloading the connection multiple times to simulate real-world usage stress.

-

Ultimate Failure Load: Pulling the connection until it physically breaks to determine the maximum safety margin.

-

Slippage Measurement: Ensuring the wedge pin does not loosen significantly under vibration or tension.

FormScaffold’s Quality Promise: We Test Where It Matters

As a premier manufacturer, we don’t rely on third-party guesswork. FormScaffold operates an in-house QC laboratory equipped with advanced hydraulic tensile testing machines.

When we test our rosettes for Axial Load Resistance, we look for:

-

High Tensile Yield: Ensuring the steel grade (usually Q345/S355) meets the mechanical property requirements.

-

Weld Shear Strength: Verifying that the weld connecting the rosette to the tube is stronger than the tube itself.

-

Wedge Lock Security: Ensuring the geometry of the wedge creates a self-locking mechanism that tightens under load.

Watch our technician perform the Axial Load Test in the FormScaffold laboratory.

Why This Matters for Your Project?

Choosing a supplier who understands and verifies Axial Load Resistance means:

-

Enhanced Safety: Reduces the risk of structural collapse during concrete pouring or high-altitude work.

-

Cost Efficiency: High-strength nodes allow for larger grid sizes (fewer components needed) in your design.

-

Longevity: Components that resist deformation last longer in your rental inventory.

H3: Looking for Certified Scaffolding Solutions? Don’t compromise on structural integrity. Contact FormScaffold today for our full technical data sheets and test reports.