The Foundation of Safety: Analyzing Raw Materials in Ringlock, Cuplock, and Frame Scaffolding

The Foundation of Safety

Introduction: The Hidden Cost of Cheap Steel In the construction industry, scaffolding is the lifeline of your workforce. When sourcing scaffolding from China, many buyers focus solely on the “price per ton,” overlooking the critical factor that dictates safety and longevity: the Raw Material. As a leading expert in formwork and scaffolding solutions, we are here to analyze the material science behind the systems and explain why we strictly adhere to a “No Non-Standard Product” policy.

Steel pipes used for making scaffolding.

1. Material Comparison: Q235 vs. Q345 Steel

The backbone of any scaffolding system lies in the grade of steel used. The two primary types are Q235 and Q345.

-

Q235 (Standard Carbon Steel):

-

Pros: Good ductility, easy to weld, and cost-effective.

-

Best For: Frame Scaffolding and standard Cuplock systems.

-

Limitations: Lower yield strength compared to Q345. If the wall thickness is compromised, it is prone to bending under heavy loads.

-

-

Q345 (High-Strength Low-Alloy Steel):

-

Pros: High tensile strength (30% stronger than Q235) and excellent load-bearing capacity.

-

Best For: Ringlock Scaffolding standards and ledgers.

-

Why it matters: For high-rise projects and bridge construction, Q345 ensures structural integrity with less material weight.

-

2. System-Specific Analysis

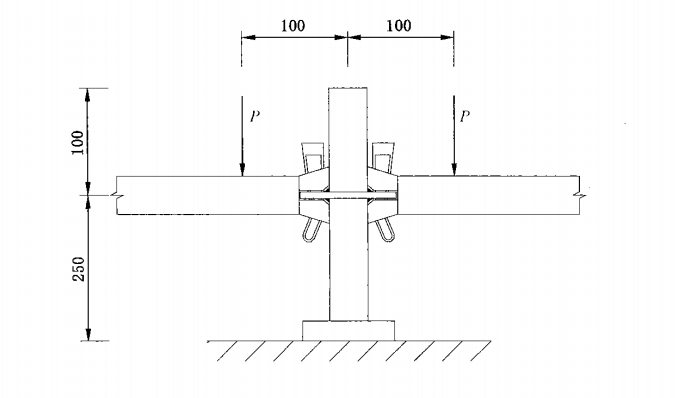

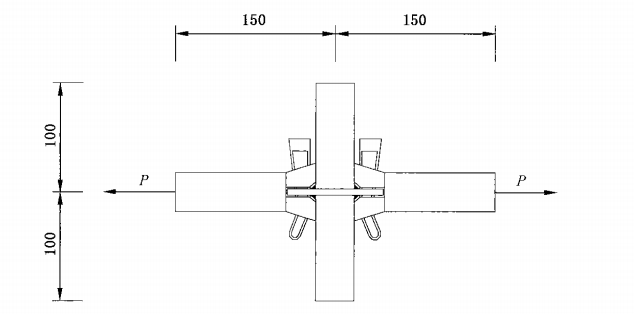

A. Ringlock Scaffolding – The High-Performance Choice

-

Material Standard: High-quality Ringlock Standards (Verticals) must use Q345B steel.

-

Durability: When combined with Hot Dip Galvanization (HDG), premium Q345 steel offers a lifespan of 15+ years.

-

The Trap: Cheap Ringlock in the market often uses Q235 steel disguised as Q345. While it looks the same, its load capacity is dangerously lower.

B. Cuplock Scaffolding – The Versatile Veteran

-

Material Standard: Typically utilizes Q235, though heavy-duty versions use Q345.

-

Durability: Offers a balance between cost and performance.

-

Key Factor: The quality of the top and bottom cups is vital. We use drop-forged or high-grade cast steel to prevent cracking—a common issue with inferior recycled steel components.

C. Frame Scaffolding – Lightweight yet Critical

-

Material Standard: Predominantly Q235.

-

Strength Factor: Since Frame systems are often used for facade work, stability relies heavily on Wall Thickness.

-

Our Standard: The market is flooded with “non-standard” frames with dangerously thin walls (e.g., <1.5mm). We refuse to produce these. We adhere strictly to international thickness standards (e.g., conforming to OSHA or EN regulations) because even a 0.2mm reduction compromises safety.

3. Why We Say NO to “Non-Standard” Products

In a competitive market, some manufacturers cut corners by using lower-grade steel or reducing pipe thickness (e.g., selling 3.0mm pipe that is actually 2.75mm).

We stand against this practice.

-

Safety First: Structural failure is not an option. Inferior raw materials lead to buckling and catastrophic collapse.

-

ROI (Return on Investment): While our standard products may have a slightly higher upfront cost, their superior durability and reusability significantly lower the cost-per-project over time.

-

Reputation: We build long-term partnerships. When you buy from us, you are buying certified quality, not just steel pipes.

Conclusion Quality scaffolding is an investment in safety and efficiency. Whether you need the high load capacity of Ringlock or the speed of Frame scaffolding, we guarantee that every tube meets strict material specifications.

📩 Looking for a reliable supplier who prioritizes quality? Contact us today for a professional solution and quote!