Stop Buying “Cheap” Plywood: A Cost-Benefit Analysis of PP vs. Traditional Film Faced Plywood

In the competitive world of construction and formwork, the initial price tag often dictates the purchase decision. But ask any veteran site manager: The cheapest sheet is often the most expensive one in the long run.

Today, we compare the rising star—PP (Polypropylene) Membrane Plywood—against the traditional Phenolic Film Faced Plywood. Is the upgrade worth it? Let’s look at the numbers.

1. The Core Difference: Plastic vs. Paper

The fundamental difference lies in the surface.

-

Traditional Film Faced Plywood: Uses a paper film impregnated with phenolic resin. It is brittle. Once scratched (by steel bars or scaffolding tubes), water penetrates, causing the wood core to swell and rot.

-

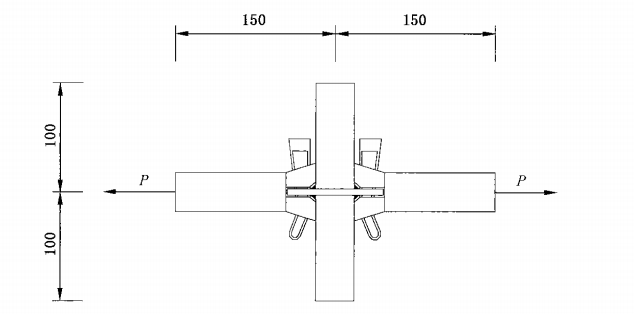

PP Membrane Plywood: Uses a 0.5mm solid Polypropylene plastic layer. It is flexible, wear-resistant, and chemically bonded to the wood. It acts as a permanent armor against water and concrete acidity.

2. The Math: Cost Per Use (The “Hidden” Saver)

Let’s assume a project requires 30 concrete pours for a high-rise building.

-

Scenario A: Traditional Plywood

-

Average Lifespan: 8–10 uses.

-

To complete 30 pours, you need to buy and replace the plywood 3 times.

-

Hidden Costs: 3x shipping costs, 3x labor for stripping and re-installing worn-out boards, plus project delays.

-

-

Scenario B: PP Membrane Plywood

-

Average Lifespan: 30+ uses.

-

To complete 30 pours, you buy it once.

-

Result: Even if PP Plywood costs 20-30% more per sheet initially, your Total Material Cost drops by over 50% by the end of the project.

-

3. Surface Quality: Save on Labor

Labor costs in Europe, North America, and Australia are high. PP Plywood produces a Class A (Fair-faced/Mirror) concrete finish. The surface is so smooth that:

-

No Release Agent Needed: Concrete doesn’t stick to PP plastic.

-

No Secondary Plastering: The wall comes out smooth, reducing the need for grinding or cement plastering.